technofab90@gmail.com - GST NO. : 24AABFT8936F1Z3

- Send Email

25 piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Automatic Grade | Automatic |

| Power source | Electric |

| Click to view more | |

Product Details

Material

Stainless Steel

Weight

5 T

Usage

Industrial

Capacity

100kg / Hr to 2000 kg /hr

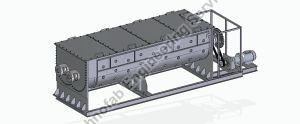

Paddle Dryer is a highly efficient, mechanically agitated, indirect heat transfer device that adds or removes heat from a process mass. It is used for indirect drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.

Dual counter-rotating shafts with unique intermeshing wedge shape paddles produce intimate mixing and optimize heat transfer. The use of hollow paddles for heat transfer results in a compact machine. The heat transfer medium: steam, oil, thermal fluid, water, or glycol is isolated from the process mass.

Advantages

- High thermal efficiency

- Heat transfer medium does not come into contact with the product.

- Gas is not used to convey the product. Off-gas flow is minimal.

- Precise control of temperature

- Uniform product quality, through mixing and movement of the product

- Continuous process on a once-through basis

- High heat transfer area to process volume ratio - reduced floor space

- Pre-conditioning with recycle is typically not required.

- Easy to operate, requires minimal attention

- Safer than direct drying when processing combustible material

- Simple durable design for easy and low maintenance

- Enclosed process contains odors and hazardous materials

Application

- Drying Heating & cooling Process

- Chemical: salts, catalyst, brominated organics, cellulose, starch

- Polymer and plastic: polypropylene, polycarbonate, poly phenyl sulfide, PET, PTA

- Mineral and metal: metal powders, metal carbonates, sulfates and hydroxides

Looking for "Paddle Dryers" ?

piece