technofab90@gmail.com - GST NO. : 24AABFT8936F1Z3

- Send Email

25 piece (MOQ)

| Business Type | Manufacturer, Exporter |

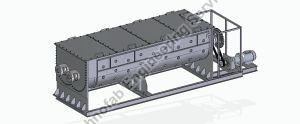

| Type | Contra Rotary Mixer |

| Material | Stainless Steel |

| Use | Industrial Use |

| Click to view more | |

Product Details

Grade

AISI, ASTM, DIN, Automatic

Voltage

440V, 230V

Condition

New

Capacity

2000-4000L, 000 Liters

Finishing

Polished

Power

15-20Kw

Warranty

1 Yr, 1 Year

Orientation

Vertical

Surface

Polished

Contra Mixer as the name suggests works on the principle of Contra rotation of Blades for simultaneous beating and scraping operation. The mixer is highly versatile and mostly used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.

The contra rotary mixture is so designed to withstand high vacuum applied during the process for optimum mixing. The mixer is provided with a jacket for cooling or heating as per the application.

We offer Contra mixer suitable for manufacturing Tooth Paste, High viscous Creams, viscous Cosmetics products and other viscous products mix.

Salient Features

- Compact design requires comparatively smaller floor space.

- Product container mounted on mounting lugs or legs as required by customer.

- Hydraulic power pack with cylinders are provided for lowering and lifting movement of top cover with stirrer's drive assembly. Lowering and lifting movement of drive assembly will be achieved through hydraulic lifting system for easy of cleaning and changeover of products. (OPTIONAL - Provided On Demand).

- Fixed product container for safe operation during mixing.

- As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem.

- Steam circulation jacket for mixing bowl, to heat the product during operation & water circulation facility to cool the product during or after mixing. (made out of mild steel or SS304, as per customer requirement).

- Material discharge from bottom. Flush bottom valve provided for material discharge.

- M/C provided with Light glass, Sight glass, material inlet, water inlet, steam & washing water inlet, air suction valve for vacuum, vacuum gauge etc.

- Mixing assembly have two speed facility. Variable speed drive facility for mixing assembly will be provided on extra cost, as an OPTIONAL facility.

- Spray ball assembly to effectively SIP.

Looking for "Contra Rotary Mixer" ?

piece