technofab90@gmail.com - GST NO. : 24AABFT8936F1Z3

- Send Email

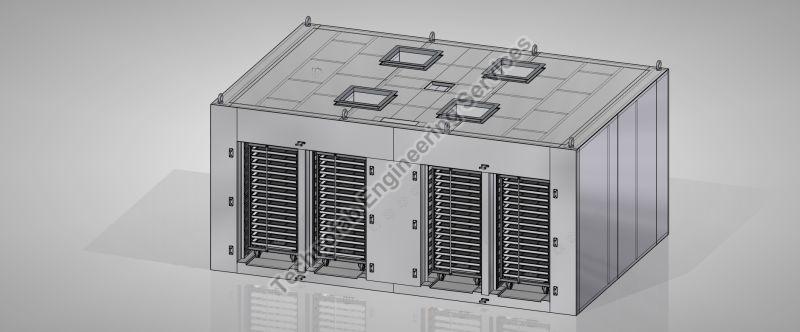

Engineered System

Leading Manufacturers, Exporters, Wholesaler and Retailer of Agitated Nutsche Filter Dryer, Agitated Thin Film Dryer, Chain-Drag conveyor, closed loop cooling tower, Contra Rotary Mixer, Contra Rotary Mixer, Fin Tube Heat Exchangers, Horizontal PADDLE DRYER, Large Storage Tanks, Paddle Dryers, PTFE OVEN (TRAY DRYER), Rotary Vacuum Dryer, Vertical Conical Dryer (Nauta Dryer), Wet Grinding machines, PET Recycling System, Centrifugal Blower and Flaker from Navsari.

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Material | Stainless Steel |

| Finishing | Polished |

| Shape | Round |

| Condition | New |

| Power | 25Kw |

| Operating Type | Semi Automatic |

| Application | Pharma Industry |

| Certification | CE Certified |

| Voltage | 440V |

| Operating Temperature | 100 C |

| Working Pressure | VACUUM /4KG/CM2 |

| Filtration Capacity | 40 Microns |

| Specialities | High Quality |

| Warranty | 1 Year |

| Country of Origin | India |

| Working Volume Cubic Meters | 5 TO 8 CU .M. |

| Filtration Area Square Meter | UP TO 8 SQ M |

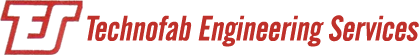

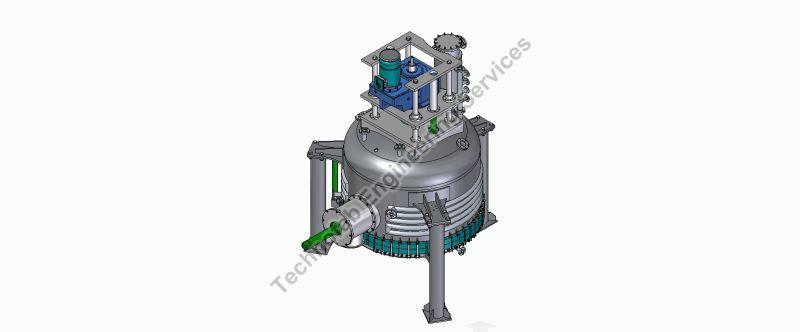

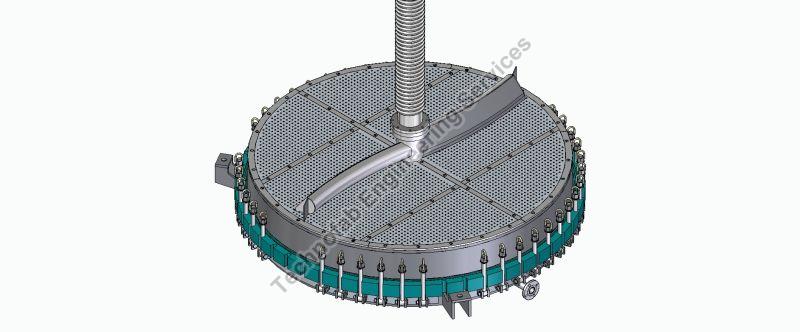

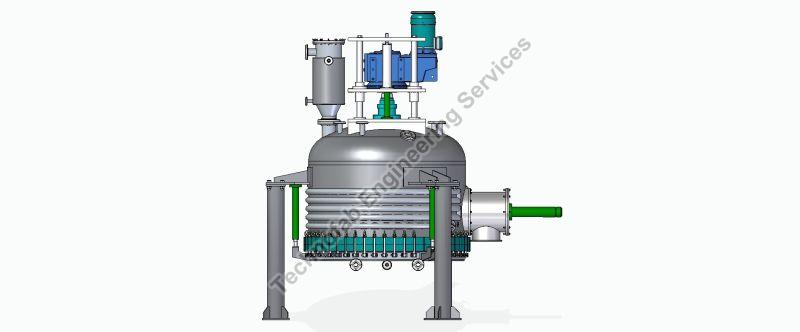

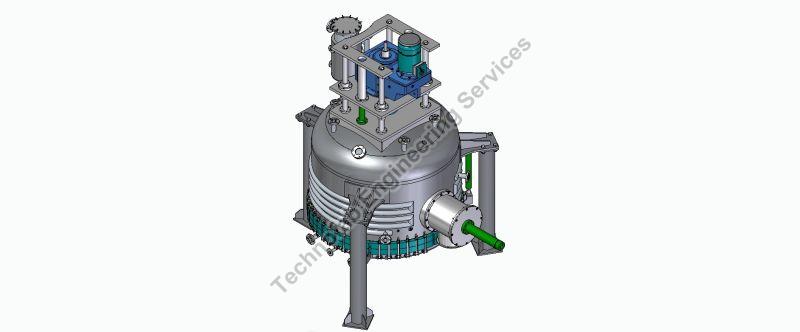

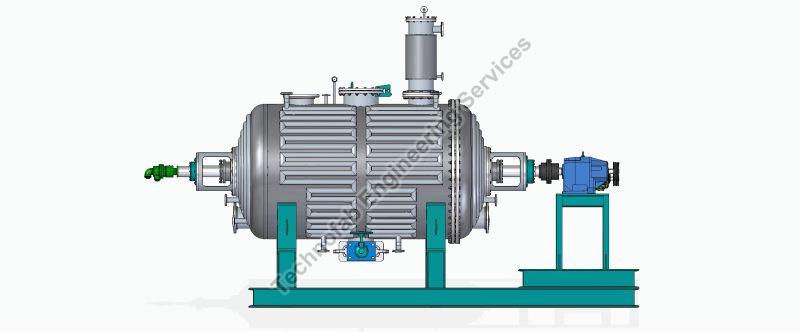

AGITATED NUTSCHE FILTER DRYER (Removable Type)

Agitated Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed operation ensures odorless, contamination free and nonpolluting working conditions maintaining product purity and hygiene. The advanced technology of agitation and hydraulics used in the equipment makes it versatile and user friendly. The resulting wet cake can be re-slurried and washed thoroughly with water or solvents.

Wash liquid quantity can be controlled and recycled, reducing effluent load. The discharge of wet cake is automatic. If the process demands filtration in chilled or hot condition, it is also possible. Drying of wet cake is also possible when drying features are incorporated.

Advantages

- The equipment is functionally safe and easy to operate.

- It can carry out various phase of process operations, viz: Crystallization , filtration, extraction, Discoloration, Washing and drying.

- The number of conventional machines employed for filtration process are also reduced.

- It has multi- functional utility, saves on power, labor, floor space, material wastage and time.

Applications : The filter dryer has wide field of applications in chemical, pharmaceutical, Agro chemicals, fine chemicals, and food industries.

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Material | HASTALLOY AND DUPLEX STEEL |

| Finishing | Polished |

| Color | Blue |

| Condition | New |

| Power | 20kW |

| Power Source | Electric |

| Motor Power | 10HP, 30 HP |

| Automatic | Semi Automatic |

| Usage | Chemical Industry |

| Voltage | 440V |

| Display Type | Digital |

| Packaging Type | Packet |

| Overall Length | 5-6 METERS |

| Specialities | Precise Design |

| Dryer Capacity | 500-1200 KG/HR |

| Type | Agitated Thin Film Dryer |

| Weight | 5000-7500 KGS |

| Frequency | 40-50Hz |

| Working Temperature | 100-150 C |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Steam Pressure | UP TO 9 KG/CM2 |

| Drying Temperature | VARIABLE |

| Output Moisture | 5% |

| Rotary Speed RPM | 100 |

| Steam Consumption | 125% |

We are the leading designers, manufacturers, and suppliers of Agitated Thin film dryers and evaporators with efficient energy utilisation

We design and supply the system in SS304, SS316, Duplex steel and Hastalloy -C276

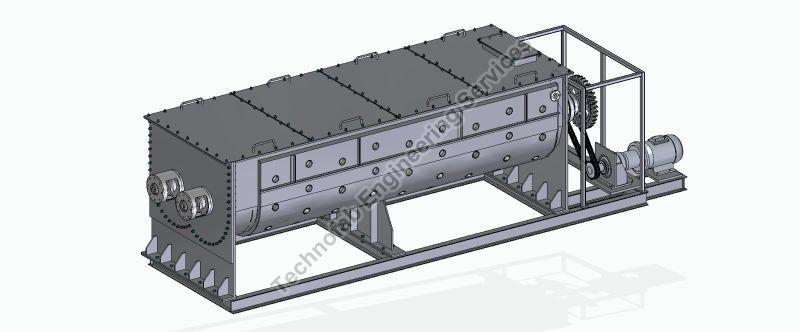

| Business Type | Manufacturer |

| Type | Drag Chain Conveyor |

| Certification | GMP |

| Length | 60-70eet |

| Application | Moving Goods |

| Color | Silver |

| Feature | Excellent Quality |

| Condition | New |

| Finishing | Polished |

| Load Capacity | >1000 Kgs |

| Brand Name | TECHNOFAB |

| Product Code | 84283900 |

| Port | MUMBAI |

| Payment Terms | D/P |

| Delivery Time | 8-10 WEEKS |

| Packaging Details | WE CAN PACK THE PRODUCT IN WOODEN BOX AND TRANSPORT THE SAME TO CLIENT'S DESTINATION |

How a tubular drag conveyor works

A tubular drag conveyor gets its name from the tubular housing that encloses a continuous chain. A drive sprocket inside a drive assembly engages the chain at the turn located at the conveying leg's end, and circular discs called flights are attached to the chain at regular intervals. The flight material is UHMWPE. This material possesses excellent physical as well as frictional properties at the same time lighter in weight most inert to various products to be conveyed, provide a quick release of sticky materials without wearing the conveyor bends and housing

Tubular Cable Conveyors (also known as Disc Conveyors and Drag Conveyors) gently slide bulk materials through smooth stainless steel tubing using low-friction polymer discs attached to the stainless steel cable. The discs and cable are driven by a Geared drive connected with a sprocket wheel at one end and a sprocket wheek with tensioner at the other end. This design allows single or multiple inlets and outlets, and the routing of conveyor tubing horizontally, vertically, or at any angle, through small holes in walls or ceilings. Because components are modular, inlets and outlets can be added, removed, or relocated, and the circuit lengthened, shortened or re-routed as needs change.

A tubular drag conveyor's lower electrical power consumption means it has much lower operating costs and as a result, a much lower long-term ownership cost. Low maintenance cost, Very smooth, silent operation, No dust filter requirement.Multiple feeds and discharge points

| Business Type | Manufacturer |

| Material | FRP, Stainless Steel |

| Driven Type | Electric, Hydraulic |

| Color | Blue |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 9-12kw |

| Application | Process Cooling |

| Certification | CE Certified |

| Voltage | 440V.580V |

| Capacity | 100TR To 300TR |

| Type | Closed Circuit Cooling Tower |

| Warranty | 2years |

| After-Sales Service Provided | Yes |

| Country of Origin | India |

| Temperature | 0-50℃ |

The closed-loop cooling tower is a hybrid of a counter-current forced-draught cooling tower and a water-to-water heat exchanger tube bundle. This cooling tower has several advantages over other types of cooling towers. Firstly, the cooling water never gets contaminated with dusty atmospheric air, which helps maintain the quality of the water. Secondly, since the cooling water circulates in a closed loop, there is no evaporation loss, which makes it an energy-efficient option1.

Jacket cooling in reactors is a beneficial feature as it prevents scaling and accumulation of mud, ensuring a very clean operation1.

| Business Type | Manufacturer, Exporter |

| Type | Contra Rotary Mixer |

| Material | Stainless Steel |

| Use | Industrial Use |

| Grade | AISI, ASTM, DIN, Automatic |

| Voltage | 440V, 230V |

| Condition | New |

| Capacity | 2000-4000L, 000 Liters |

| Finishing | Polished |

| Power | 15-20Kw |

| Warranty | 1 Yr, 1 Year |

| Orientation | Vertical |

| Surface | Polished |

Contra Mixer as the name suggests works on the principle of Contra rotation of Blades for simultaneous beating and scraping operation. The mixer is highly versatile and mostly used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.

The contra rotary mixture is so designed to withstand high vacuum applied during the process for optimum mixing. The mixer is provided with a jacket for cooling or heating as per the application.

We offer Contra mixer suitable for manufacturing Tooth Paste, High viscous Creams, viscous Cosmetics products and other viscous products mix.

Salient Features

- Compact design requires comparatively smaller floor space.

- Product container mounted on mounting lugs or legs as required by customer.

- Hydraulic power pack with cylinders are provided for lowering and lifting movement of top cover with stirrer's drive assembly. Lowering and lifting movement of drive assembly will be achieved through hydraulic lifting system for easy of cleaning and changeover of products. (OPTIONAL - Provided On Demand).

- Fixed product container for safe operation during mixing.

- As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem.

- Steam circulation jacket for mixing bowl, to heat the product during operation & water circulation facility to cool the product during or after mixing. (made out of mild steel or SS304, as per customer requirement).

- Material discharge from bottom. Flush bottom valve provided for material discharge.

- M/C provided with Light glass, Sight glass, material inlet, water inlet, steam & washing water inlet, air suction valve for vacuum, vacuum gauge etc.

- Mixing assembly have two speed facility. Variable speed drive facility for mixing assembly will be provided on extra cost, as an OPTIONAL facility.

- Spray ball assembly to effectively SIP.

| Business Type | Manufacturer |

| Material | Stainless Steel |

| Finishing | Polished |

| Color | Metallic |

| Condition | New |

| Power | 15-20Kw |

| Application | Industrial Use |

| Grade | ASTM |

| Voltage | 220V,440V |

| Capacity | 1000-2000L,2000-4000L |

| Type | Contra Rotary Mixer |

| Warranty | 1 Yr |

| Country of Origin | India |

| Orientation | Vertical |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Some of its features are:

� High durability

� Low maintenance cost

� Trouble free operation

Applications of finned tube heat exchangers:

� Steam air heater / steam radiator

� Thermic fluid air heater / thermic fluid radiator

� Hot water air heater / hot water radiator

� Air heater for fluid bed dryers

� Air heater for spray dryers

� Air heater for flash dryers

� Air heater for dryers

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Material | SS |

| Finishing | Polished |

| Color | Silver |

| Condition | New |

| Power | 50 TO 90 KW |

| Power Source | Electric |

| Motor Power | 50HP,100HP |

| Automatic | Semi Automatic |

| Usage | Chemical Industry |

| Voltage | 440V |

| Display Type | Digital |

| Capacity | 250 KG/HR TO 1500 KG/HR |

| Packaging Type | PLASTIC WRAPPING |

| Specialities | Fine Finish,Precisely Designed |

| Type | Dryers |

| Frequency | 40-50Hz |

| Working Temperature | 100-200 C |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Max Temperature | 200 |

| Steam Pressure | 9 KG/CM2 |

| Heating Media | STEAM |

| Output Moisture | 5-% |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Clinical, Hospital |

| Finishing | Polished, PAINTED |

| Color | Customize |

| Condition | New, Good |

| Type | Vacuum Extractor |

| Available Silicone Cups Size | 40, 50, 60 mm |

| Noise Level (Decibel): | 50dBA |

| Polishing | Yes |

The Extractor is specially designed High Vacuum Distillation Unit that comprises multi-bladed stirrer design with a set of fixed & moving blades. The bottom set is specially designed blades, one set having pin-type construction & another sweeper profile to match the bottom dish profile in closed proximity. The distillation is done under high vacuum condition to achieve effective separation by distillation at relatively low temperature, especially to suit the heat sensitive product.

Since the extraction is achieved up to the last drop one can get rid of the effluent problem during the operation. The total operation is carried out in an enclosed environment there is no environmental adverse effect. You can achieve zero discharge process.

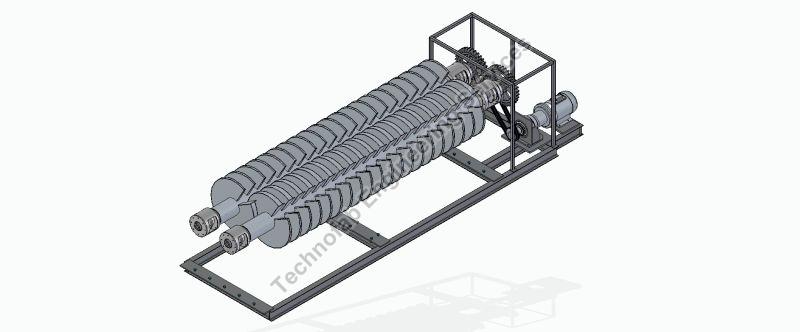

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Automatic Grade | Automatic |

| Power source | Electric |

| Material | Stainless Steel |

| Weight | 5 T |

| Usage | Industrial |

| Capacity | 100kg / Hr to 2000 kg /hr |

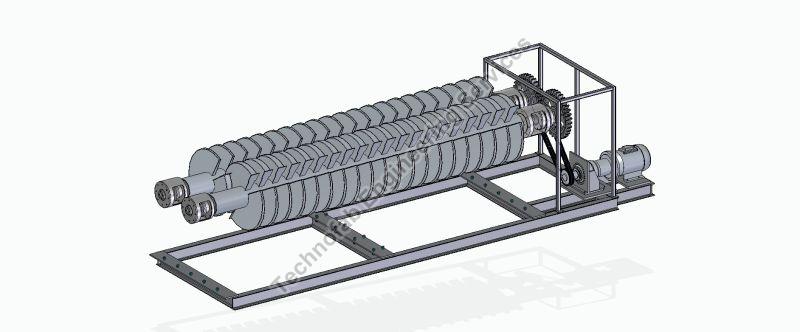

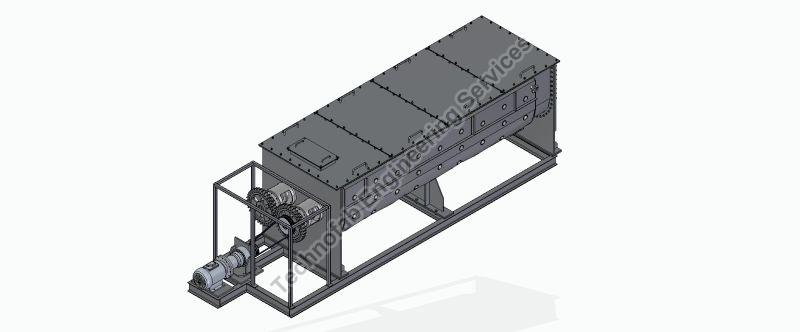

Paddle Dryer is a highly efficient, mechanically agitated, indirect heat transfer device that adds or removes heat from a process mass. It is used for indirect drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.

Dual counter-rotating shafts with unique intermeshing wedge shape paddles produce intimate mixing and optimize heat transfer. The use of hollow paddles for heat transfer results in a compact machine. The heat transfer medium: steam, oil, thermal fluid, water, or glycol is isolated from the process mass.

Advantages

- High thermal efficiency

- Heat transfer medium does not come into contact with the product.

- Gas is not used to convey the product. Off-gas flow is minimal.

- Precise control of temperature

- Uniform product quality, through mixing and movement of the product

- Continuous process on a once-through basis

- High heat transfer area to process volume ratio - reduced floor space

- Pre-conditioning with recycle is typically not required.

- Easy to operate, requires minimal attention

- Safer than direct drying when processing combustible material

- Simple durable design for easy and low maintenance

- Enclosed process contains odors and hazardous materials

Application

- Drying Heating & cooling Process

- Chemical: salts, catalyst, brominated organics, cellulose, starch

- Polymer and plastic: polypropylene, polycarbonate, poly phenyl sulfide, PET, PTA

- Mineral and metal: metal powders, metal carbonates, sulfates and hydroxides

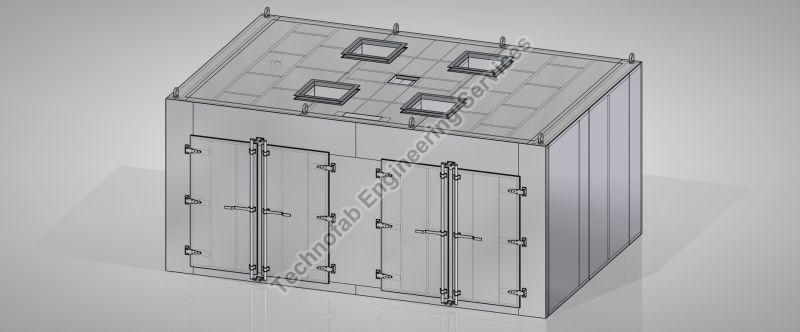

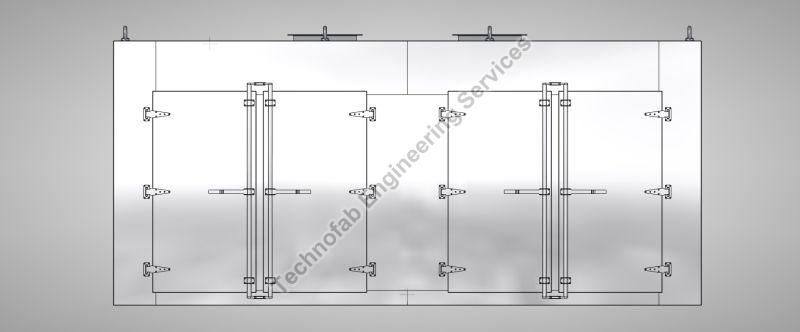

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Driven Type | STEAM |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 6-9kw |

| Power Source | STEAM/ELECTRIC |

| Application | PHARMACEUTICAL UNIT PERATIONS |

| Certification | CE Certified |

| Feature | Energy Saving Certified, Fast Heating, Rust Resistance |

| Voltage | 440V |

| Capacity | 192 TRAYS,98 TRAYS |

| Type | CLOSED TRAY DRYER |

| Frequency | 50Hz |

| Warranty | 1year |

| After-Sales Service Provided | YES |

| Country of Origin | India |

THIS IS A MODIFIED VERSION OF THE TRAY DRYER AND IS ALSO AVAILABLE IN VACUUM DRYER

tOTAL HYGENIC PRODUCT , FULLY POLOSHED INSIDE OUT WITH INSULATED WALL

WIDELY USED IN THE PHARMACEUTICAL UNIT OPERATIONS

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Material | SS |

| Finishing | Polished |

| Condition | New |

| Power | 5kW, 10kW, 15kW |

| Power Source | STEAM |

| Automatic | Semi Automatic |

| Usage | Chemical Industry |

| Voltage | 440V |

| Display Type | Digital |

| Specialities | Precise Design, Fine Finish |

| Dryer Capacity | 100 - 1000 KG/BATCH |

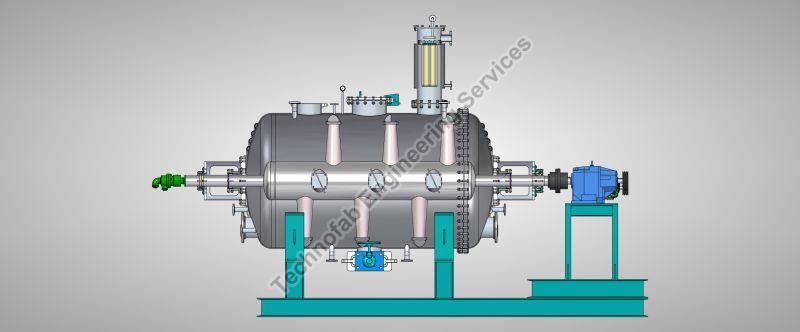

| Type | Rotary Vacuum Dryer |

The drying operation is achieved under high vacuum conditions using a horizontal, cylindrical agitated blender cum dryer. The core of the rotor has multiple blades, and live steam enters through one end and circulates throughout the dryer length and across the cross-section. Additional heat is given through the limpet coil.

The main advantage of this dryer is that it provides a very high heat transfer area up to the center of the dryer. Additionally, the drying is done under high vacuum conditions, which helps maintain the quality of the product1.

| Business Type | Manufacturer |

| Brand Name | TECHNOFAB |

| Material | SS |

| Finishing | Polished |

| Condition | New |

| Power | 5kW, 10kW, 15kW |

| Power Source | Electric |

| Automatic | Semi Automatic |

| Usage | Chemical Industry |

| Voltage | 440V |

| Display Type | Digital |

| Overall Length | AVAILABLE IN VARIOUS SIZES |

| Specialities | Precise Design, Fine Finish |

| Dryer Capacity | 250 TO 1000 KG/BATCH |

| Type | Conical Vacuum Dryer |

| Frequency | 40-50Hz |

| Working Temperature | 150 |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

The vertical conical or Nauta dryer is an efficient method of drying process equipment.

As the name suggest it is a conical bottom and top Dish end equipment with coaxial siirrer arrangement

The stirrer rotates in the plenatary motion giving very effective belnding and drying

The material of construction can be Stainless steel, Duplex steel ,or any high Nickle alloy steel

| Business Type | Manufacturer, Exporter |

| Payment Terms | D/P |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Certification | Ce Certified |

| Weight | 100-500kg |

| Voltage | 380V |

| Condition | New |

| Power | 3-5kw |

| Driven Type | Hydraulic |

| Warranty | 1 Year |

| After-sales Service Provided | Spare Parts |

We are into Designing Manufacturing and Exporting PET Recycling System, which is engineered with precision to match the high industrial standards. We offer wash line equipment with total design. We provide the layout details / drawing along with the design to the clients. The Pet Recycling System is widely used for recycling pet bottles by converting used bottles into flakes.

Equipment we can supply :

- Pre wash tank and Reactor with agitator

- Sink float Tanks, Screw conveyor

- Bale breaker

- Trommel

- Spin dryer

- Hot air Generator

- Drying cum Pneumatic converging set up

Salient Features :

- Longer working life

- High performance

- Low maintenance cost

- Robust structure

Uses :

- Recycling of PET bottles

- Converting the used PET bottles in to flakes

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Centrifugal Blower, offered by us, is manufactured using latest technologies for high efficiency and durability. We offer Centrifugal Blower in different volume flow rate & static pressure as per the specifications of the clients. These Centrifugal Blowers are available in various material of construction to meet the demands of the buyers.

Known for :

· High performance

· Durability

· Low maintenance cost

· Optimum quality

· Less noise operation

Applications :

· Automotive industry

· Pharmaceuticals industry

· Chemical Plants

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We are engaged in Manufacturing and Exporting Flaker, which converts molten mass into solid flakes. The Flaker is specially designed with utmost precision for the continuous duty. We can also offer variable speed drive system as per client’s requirement. We supply high performing Flaker in the foreign markets.

Material of construction :

· Stainless steel

Special Features :

· Trouble free economical operation

· Continuous Process

· High thermal efficiency

· Controlled thermal degradation

· Single step operation

· Uniform flakes

Process :

· Forming thin layer of the molten mass on the outer surface of the drum rotating at very low RPM

· The layer is cooled by the water circulation through the drum

· Adjustable scrapper continuously scraps the solidified flakes from the drum and the flakes are collected into bags or the containers